Advanced Magnetic Materials Processing (AM2P) Lab

Materials processing is a core aspect of Materials Science & Engineering. How a material is shaped greatly influences its structure—crystallographic, phase, micro-, and macrostructure—and, in turn, its properties and performance. It also determines the final product's functionality and is central to materials selection and design.

At VCU, our Advanced Magnetic Materials Processing (AM2P) lab focuses on fundamental microstructure studies to develop high-performance functional magnetic materials. We integrate advanced processing methods with cutting-edge experimental and computational techniques to understand the links between processability, structure, and functional response across multiple length scales. Our work aims to precisely tune properties for magnetic device applications.

This research is supported by funding from various agencies and industry partners, including the Commonwealth Cyber Initiative (CCI), Commonwealth Center for Advanced Manufacturing (CCAM), Venturewell Foundation, US Ignite, Higher Education Equipment Trust Fund (HEETF), and the National Science Foundation (NSF).

1. Next-Gen Permanent Magnets via

Additive Manufacturing

Permanent magnets are essential in consumer and industrial electronics, renewable energy technologies (such as wind turbines, hydroelectric generators, and electric vehicles), and many other applications. Current magnets in clean energy solutions rely on critical rare-earth elements (neodymium, dysprosium, samarium, terbium, praseodymium), which pose environmental, geopolitical, and economic challenges. We aim to advance magnetic materials through innovative additive manufacturing techniques, multiscale modeling, and experimental validation. Our long-term goal is to develop sustainable, high-performance solutions for the challenges of modern technology.

Material Innovation:

Designing and fabricating phase-engineered magnetic alloys (e.g., Alnico, Fe-Mn-based exchange biased systems).

Techniques:

Utilizing laser-based metal additive manufacturing methods such as Directed Energy Deposition (DED) and Laser Powder Bed Fusion (PBF) to achieve precise control over composition, microstructure, and phase separation.

International Partners

Combining multiscale modeling, advanced characterization, and real-time thermal monitoring.

Develop magnets with competitive energy products and thermal stability for electrified transportation, renewable energy, and defense—without the supply chain risks associated with rare-earth materials.

Long-Term Goal:

Visual Highlights:

-

DED system used for 3D printing magnets

-

Columnar microstructure in 3D printed Alnico magnets

-

Magnetic hysteresis loops (with Lorentz microscopy insets)

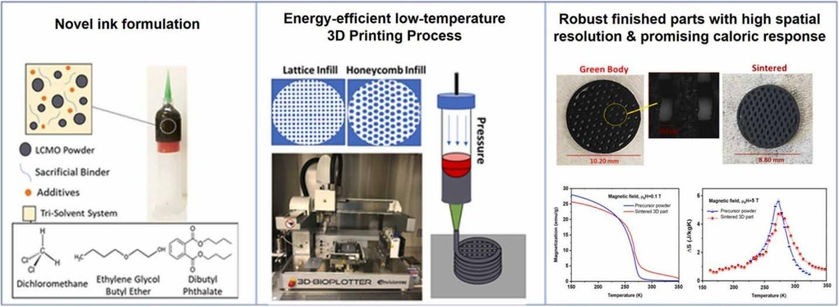

2. Caloric Materials for Magnetic Heat Pump Applications

In the U.S., the commercial building sector accounts for 18% of total end-use energy, with one-third used for on-site fossil fuel heating. Electrification via heat pumps could reduce HVAC-related CO₂ emissions by 142 million metric tons annually and cut water heating energy use by up to 50%. Yet, many heat pumps still rely on high-GWP refrigerants.

Magnetic Heat Pumps (MHPs): Leveraging magnetocaloric technologies to achieve 30% greater efficiency, eliminate refrigerant leakage, and provide a climate-friendly alternative.

Our Approach:

Magnetic Field Sources:

Optimized for efficiency, size, and system integration.

Material Innovation:

Designing and fabricating phase-engineered magnetic alloys (e.g., Alnico, Fe-Mn-based exchange biased systems).

Techniques:

Utilizing laser-based metal additive manufacturing methods such as Directed Energy Deposition (DED) and Laser Powder Bed Fusion (PBF) to achieve precise control over composition, microstructure, and phase separation.

International Partners

Combining multiscale modeling, advanced characterization, and real-time thermal monitoring.

Methodology:

Using finite element modeling and experimental validation, our team designs advanced magneto-thermal architectures with improved heat transfer and reduced fluid resistance. Additive manufacturing allows for scalable production of tailored magnetocaloric structures, and a concurrent techno-economic analysis ensures a focus on energy equity and accessibility.

3. Electromagnetic Shielding Materials for High Frequency Devices

As the Internet of Things (IoT) expands, securing cyber-physical systems against electromagnetic interference (EMI) becomes increasingly critical. Modern systems are vulnerable to electromagnetic jamming and related cyber-attacks that can affect telecommunications, financial systems, and manufacturing.

Magnetic Heat Pumps (MHPs): Leveraging magnetocaloric technologies to achieve 30% greater efficiency, eliminate refrigerant leakage, and provide a climate-friendly alternative.

Our Approach:

Magnetic Field Sources:

Optimized for efficiency, size, and system integration.

Material Innovations:

Exploring magnetic nanoparticles, carbon-based nanostructures (e.g., nanotubes, graphene, MXene), conductive polymers (e.g., PDMS, PVB, PaNi), and their hybrids for EMI shielding.

Challenge:

Achieving broadband shielding that meets the size, weight, power, and cost (SWaP+C) requirements of 5G devices.

Focus:

Developing magnetic films and filaments made from a thermally conductive polymer filled with magnetic nano ferrite powders for the additive manufacturing of lightweight, flexible EM absorbers. These absorbers target the high-frequency range of 4–18 GHz.

The AM2P lab at VCU is dedicated to addressing modern challenges in magnetic materials. Through innovative additive manufacturing, detailed modeling, and thorough experimental research, we are pioneering solutions that advance renewable energy, efficient heating, and secure communications. Our research continues to push the boundaries of what is possible in the fields of permanent magnets, magnetocaloric systems, and electromagnetic shielding.